- タイキグループ

- TAIKI GROUP

- Our Services

- Quality Control

Quality Control

Systemization from development to mass production

Taiki Group has built a production system that can handle all processes from product development and design stage to raw material procurement, mass production, and delivery.

In addition to complying with legal and regulatory requirements, we are quickly working on the implementation of cosmetic GMP (ISO22716), adopting an advanced quality management system, and a production system that is recognized worldwide. In each process of development and production, inspectors strictly check based on quality assurance according to customer requirements.

While evaluating safety and functionality at the development stage, multiple inspections are conducted, including acceptance inspections and intermediate product inspections at the production stage, and final inspections after filling and packaging. In addition, we will continue to inspect the stability and quality of products after shipment, and feed back the results to the development department, aiming to provide higher quality products.

Development Stage

- Safety test

- Stability test

- Functionality evaluation

Production Stage

- Acceptance inspection of raw materials

- Formulation and bulk quality inspection

- Filling process inspection

- Online inspection

- Offline inspection

Shipment Stage

- Pre-shipment inspection

- Post-shipment inspection

Delivery

Development Stage

Safety test

The safety of both raw materials and pharmaceuticals is checked by various safety tests to determine irritation and allergenicity, including prototype patch tests.

Stability test

To ensure long and safe use, check for problems under various assumed conditions. In addition to various measuring devices, we also check the appearance, color, smell, etc. based on the senses of the inspector.

Functionality evaluation

In accordance with JIS, ISO, or the evaluation standards established by TAIKI,the functionality is checked using various devices by confirming whether the quality standards are met or whether the functions are being demonstrated correctly.

Production Stage

Acceptance inspection of raw materials

For the materials procured, we will inspect the conformity of standards and the functionality of containers.

Formulation and bulk quality inspection

Using various inspection equipment such as viscosity inspection, usability inspection, and microbiological inspection. The appearance, smell, and ease of use are checked.

Filling process inspection

At the time of filling, visual inspection by line staff, inspection of scratches, foreign matter contamination, weight inspection, etc. are also performed.

Delivery Stage

Pre-shipment inspection

Sampling inspection is conducted by an inspector. Only those products that have passed strict check such as appearance inspection, microbiological inspection, and pH inspection will be shipped.

Post-shipment inspection

We also conduct inspections to confirm the stability and quality of shipped products, such as accelerated tests and stability tests using finished products.

ISO 9001・14001・22716

ISO 9001 quality management system established by the International Organization for Standardization is acquired. Also, we acquired “ISO 14001” and “ISO 22716” as well. Furthermore, under the Taiki Group's quality policy, all employees continue to take on the challenge of improving quality and technology and work on supplying high-quality products that will earn satisfaction and trust from our customers.

YUNOS

Certification registration date:Feb. 11, 2005.

Certification expiration date:Feb. 10, 2026.

YUNOS

Certification registration date:Dec. 10, 2022.

Certification Expiration date:Dec. 9, 2025.

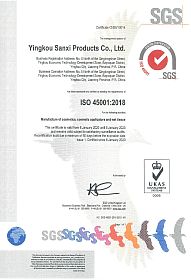

Yingkou Sanxi Products Co.,Ltd. (China)

Certification expiration date:Oct. 23, 2025.

Yingkou Sanxi Products Co.,Ltd. (China)

Certification expiration date:Jan. 5, 2026.

Yingkou Sanxi Products Co.,Ltd. (China)

Certification expiration date:Nov. 5, 2026.

Yingkou Sanxi Products Co.,Ltd. (China)

Certification expiration date:Jan. 3, 2026.

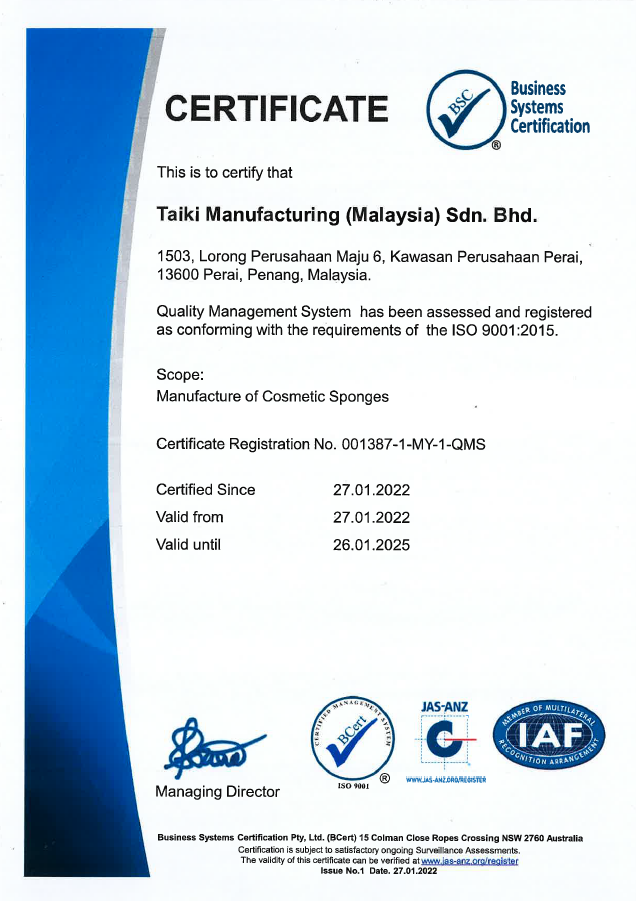

Taiki Manufacturing(Malaysia)SDN.BHD. (Penang)

Certification expiration date:Jan. 26, 2026.

Sustainable business activities

Resilience certification Obtained

「Resilience Certification」was obtained based on 「Guidelines for Certification of Organizations Contributing to Land Resilience」.

TAIKI has been certified as an enterprise that actively engages in business continuity efforts with the approval of The Cabinet Secretariat's National Resilience Promotion Office on the purpose of national resilience.

Taiki Corporation.,LTD.:I0000010

Yunos Corporation.,LTD.:E0000026

Certification registration date:Nov. 30, 2021.

Certification renewal date:Nov. 30, 2023.

Certification expiration date : Nov.29, 2025.

Supporting Members of the National Federation of UNESCO Associations in Japan(NFUAJ)

Taiki Corporation., Ltd. agrees with the purpose of NFUAJ, which has been active since 1947, and supports it as a supporting member.![]()

evaluated by EcoVadis(external assessment organization)

Taiki Group have been awarded a gold medal for Corporate Social Responsibility from EcoVadis, the world's most trusted provider of business sustainability ratings. And This medal is rated based on a sustainability scorecard which illustrates performance across 21 indicators in four main categories: environment, labor and human rights, ethics, and sustainable procurement.